1. Material Composition of Aluminum 4x6 Pergolas

When considering an Aluminum 4x6 pergola, understanding its material composition is crucial for both longevity and performance. These pergolas are primarily crafted from high-grade aluminum alloys, which offer a perfect balance between strength and lightweight design. Aluminum’s natural corrosion resistance ensures it withstands rainy or humid conditions without rusting, making it ideal for backyard or patio installations.

1.1 Types of Aluminum Alloys Used

Most 4x6 aluminum pergolas utilize 6000-series aluminum, known for its excellent strength-to-weight ratio and resistance to environmental wear. In some premium models, manufacturers integrate 6061-T6 aluminum, which is heat-treated for maximum structural integrity. This type of alloy is particularly advantageous for larger spans, like the 4x6 footprint, where support without added weight is critical.

Example of application: A homeowner installed a custom backyard Aluminum 4x6 pergola with 6061-T6 beams. The structure supports climbing plants without sagging, even in high wind conditions, showcasing how alloy choice directly impacts performance.

| Alloy Type | Tensile Strength (MPa) | Weight per Foot (kg) | Corrosion Resistance | Typical Use |

|---|---|---|---|---|

| 6005-T5 | 270 | 2.3 | High | Standard residential pergolas |

| 6061-T6 | 310 | 2.5 | Very High | Heavy-duty or commercial pergolas |

This table highlights why selecting the right alloy matters. Higher-grade alloys like 6061-T6 provide durability without heavy structural bulk, essential for maintaining a clean, minimalist aesthetic in patios or terraces.

1.2 Powder Coating and Surface Finishes

After alloy selection, surface treatment plays a key role in longevity. Powder coating creates a tough, UV-resistant layer that prevents fading and adds aesthetic appeal. Many homeowners prefer neutral tones like graphite or champagne, which complement outdoor furniture and landscaping.

Installation insight: 1) Ensure all aluminum pieces are free of oils and debris before coating; 2) Apply a uniform powder coat layer; 3) Bake the components at high temperature to cure. This process ensures a uniform finish that can last decades without chipping or peeling.

Additionally, textured or metallic finishes can mimic the appearance of wood, providing a warm, classic feel without the maintenance headaches of timber pergolas.

1.3 Structural Reinforcements

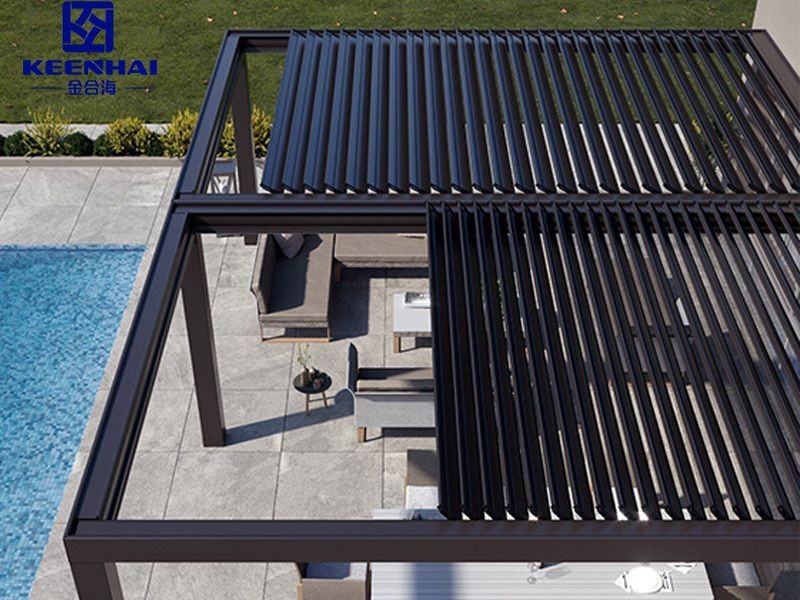

Even though aluminum is lightweight, strategic reinforcements are critical to prevent flexing over time. Pergola manufacturers often add internal crossbars, gusset plates, and corner brackets at key load points. These reinforcements distribute weight evenly, especially for heavy overhead louver systems or integrated lighting.

For instance, a terrace installation in California featured an Aluminum pergola 4x4 adjacent to a swimming pool. The reinforced posts allowed mounting retractable shades and hanging planters without noticeable deflection, demonstrating the importance of internal supports.

Step-by-step reinforcement approach:

-

Install vertical posts and ensure they are plumb.

-

Attach horizontal beams with gusset plates at all major joints.

-

Cross-check alignment and tighten all fasteners to manufacturer torque specs.

-

Add additional lateral supports if integrating louvers or heavy accessories.

This structured approach guarantees stability while keeping the pergola lightweight and sleek, ideal for modern outdoor spaces.

2. Benefits of Aluminum Pergola Materials

Choosing the right material for a pergola can make a huge difference in both performance and maintenance. Aluminum pergolas offer several advantages that make them a popular choice for homeowners and commercial spaces alike. From lightweight construction to exceptional durability, aluminum frames provide a combination of practicality and longevity that’s hard to beat.

2.1 Lightweight Yet Strong

One of the standout benefits of aluminum is its high strength-to-weight ratio. A standard 4x6 aluminum pergola weighs roughly 60–80 lbs per 10-foot section, compared to a wooden beam of the same size, which can exceed 200 lbs. This lightweight nature allows for easier transport, quicker installation, and reduced stress on the foundation.

Practical insight: During a recent rooftop terrace installation, the lightweight aluminum frame allowed a two-person team to set up a full 4x6 pergola in under four hours, without requiring heavy machinery or scaffolding. Despite being lightweight, high-grade alloys like 6061-T6 provide sufficient strength to support climbing plants, integrated lights, or retractable louvers without noticeable flexing.

2.2 Corrosion and Rust Resistance

Aluminum’s natural oxide layer gives it exceptional resistance to corrosion, which makes it ideal for humid or coastal environments. Unlike steel, it doesn’t rust, and unlike wood, it won’t rot or warp. When combined with powder-coated finishes, the material can withstand decades of sun, rain, and even salty sea air.

Example: A backyard 4x6 aluminum pergola installed near the Pacific coast showed zero signs of corrosion after five years, despite being exposed to direct salt spray and heavy rainfall. This reliability is a major reason many homeowners prefer aluminum pergolas over traditional timber options.

2.3 Low Maintenance Requirements

Maintaining an aluminum pergola is straightforward. No staining, sealing, or painting is required, unlike wood, which demands annual upkeep. Cleaning typically involves 1) rinsing with water, 2) wiping with mild soap, and 3) occasional inspection of fasteners. This minimal maintenance ensures the pergola retains its aesthetic appeal while freeing homeowners from time-consuming chores.

Scenario: In a commercial hotel courtyard, an aluminum pergola frame has remained visually pristine for over six years, requiring only light seasonal cleaning, which translates into significant cost and labor savings.

2.4 Longevity Compared to Other Materials

Aluminum pergolas can last 20–30 years or more without structural degradation when properly coated and installed. By contrast, untreated wood may deteriorate in 5–10 years depending on exposure, while steel structures can suffer rust if coatings fail.

| Material Type | Expected Lifespan | Maintenance Needed | Environmental Resistance |

|---|---|---|---|

| Aluminum | 20–30+ years | Minimal | High (UV, humidity, coastal) |

| Wood | 5–10 years | Annual sealing | Moderate (prone to rot) |

| Steel | 10–20 years | Coating required | Moderate (prone to rust) |

This table clearly illustrates why aluminum remains a top choice for both residential and commercial installations: it balances durability, low upkeep, and environmental resilience.

3. Drawbacks of Aluminum Pergola Materials

While aluminum pergolas offer many advantages, they are not without their limitations. Understanding these drawbacks ensures homeowners make informed decisions when planning outdoor spaces.

3.1 Higher Initial Cost

One of the main disadvantages of an aluminum pergola is the upfront investment. Compared to wood or vinyl, high-grade aluminum alloys like 6061-T6 or 6005-T5 can cost 30–50% more per linear foot. The price reflects long-term durability, corrosion resistance, and low maintenance, but it may not fit every budget.

Scenario: A homeowner compared a timber 4x6 pergola at $1,200 with an aluminum version costing $1,750. Despite the higher initial cost, the aluminum option required no annual staining or sealing, offsetting the price difference over 10–15 years. This makes aluminum a cost-effective choice in the long run, even if the first purchase seems steep.

3.2 Susceptibility to Denting and Bending

Although aluminum is strong relative to its weight, it is softer than steel, making it more prone to denting from heavy impacts or bending under concentrated loads. Careful handling during installation is crucial, especially for large 4x6 spans.

Example: On a residential backyard installation, a contractor accidentally dropped a toolbox on a horizontal beam, leaving a minor dent. While structurally harmless, the cosmetic impact was visible. Reinforced beams or careful post-installation checks can mitigate such issues.

Practical tip:

-

Avoid standing or placing heavy objects directly on the pergola frame.

-

Inspect crossbars and brackets after severe weather for minor deformation.

-

Choose powder-coated or textured finishes that minimize the visual effect of small dents.

3.3 Heat Conductivity and Surface Temperature

Aluminum conducts heat much more efficiently than wood or vinyl, which can cause surfaces to become hot to the touch in direct sunlight. During summer, unshaded beams can reach temperatures of 120–140°F (49–60°C), potentially uncomfortable for touching or adding accessories.

Example: A terrace pergola exposed to full sun in Arizona became too hot to hang fabric shades directly on the beams during midday. Homeowners solved this by:

-

Installing retractable louvers for shade control.

-

Adding thermal-resistant coatings to reduce heat absorption.

-

Positioning pergolas near existing shade structures when possible.

Despite these drawbacks, many homeowners find the long-term benefits of aluminum outweigh the minor inconveniences, especially when preventive measures are applied.

4. Comparison with Other Pergola Materials

When choosing a pergola, understanding how aluminum compares with other common materials is essential. Each material has its advantages and limitations, but aluminum often balances durability, maintenance, and aesthetics in a way few others can match.

4.1 Aluminum vs Wood

Strength and Weight: Aluminum is lightweight yet strong, while wood can be heavy and prone to sagging over time.

Maintenance: Wood requires annual sealing, staining, or painting, whereas aluminum pergolas need only minimal cleaning.

Durability: Untreated wood is vulnerable to rot, insect damage, and warping. In contrast, aluminum resists corrosion and UV damage.

Example scenario: A backyard pergola in Florida faced high humidity and termites. A timber pergola deteriorated within 7 years, while a sturdy Aluminum 4x6 pergola installed nearby remained structurally sound with no visible decay.

| Feature | Aluminum | Wood |

|---|---|---|

| Weight | Light (60–80 lbs per 10 ft) | Heavy (200+ lbs per 10 ft) |

| Maintenance | Minimal | Annual sealing/staining |

| Lifespan | 20–30+ years | 5–10 years untreated |

| Environmental Resistance | Excellent (UV, moisture, coastal) | Moderate (prone to rot, insects) |

4.2 Aluminum vs Steel

Corrosion Resistance: Steel is stronger but prone to rust if coatings fail. Aluminum naturally resists corrosion, making it ideal for coastal or humid environments.

Weight and Installation: Aluminum is easier to handle and install due to its lighter weight. Steel requires heavy equipment, especially for large spans.

Practical insight: A rooftop terrace installation in New York opted for aluminum beams because lifting steel beams to the rooftop would have required cranes and additional labor costs. Aluminum provided comparable structural support without the logistical complexity.

4.3 Aluminum vs Vinyl

Durability: Vinyl is resistant to rot and insects but can crack under extreme temperatures. Aluminum withstands heat and cold better, maintaining structural integrity.

Aesthetic and Finish Options: Aluminum can be powder-coated in a variety of colors, including metallic and textured finishes, while vinyl has limited color and finish options.

Example: On a desert patio installation, vinyl pergola posts warped after a summer of 115°F temperatures, whereas a nearby aluminum pergola frame retained its shape and finish, demonstrating superior performance in extreme climates.

5. Environmental and Practical Considerations

Beyond strength and durability, choosing an aluminum pergola also offers environmental and practical advantages that impact both sustainability and ease of use. Understanding these aspects helps homeowners make informed, eco-conscious choices.

5.1 Recyclability and Sustainability

Aluminum is 100% recyclable without losing its properties, making it one of the most sustainable construction materials available. Recycling aluminum consumes 95% less energy than producing primary aluminum, significantly reducing carbon footprint.

Scenario: A landscape designer replaced aging wooden pergolas in a community park with aluminum pergolas. The aluminum frames were fully recyclable at the end of their service life, while the wood would have required landfill disposal or chemical treatment to prevent decay.

Additionally, powder-coated finishes are non-toxic and low-VOC, further enhancing environmental benefits. Choosing aluminum supports long-term sustainability goals while providing a durable and low-maintenance structure.

5.2 Ease of Installation and Mobility

Aluminum’s lightweight nature and modular design make installation faster and simpler than other materials. A standard 4x6 pergola section weighs 60–80 lbs, allowing two people to handle full beams without machinery.

Installation steps:

-

Prepare the foundation or footings according to site specifications.

-

Assemble vertical posts and check for plumb alignment.

-

Attach horizontal beams and secure with corner brackets.

-

Install crossbars or louvers as needed.

-

Apply minor adjustments to ensure the structure is level and stable.

Practical example: On a rooftop terrace, a two-person team installed a 4x6 aluminum pergola in under four hours, compared to steel options that would have required cranes and extra labor. This modular flexibility also allows pergolas to be relocated or expanded more easily than wood or vinyl structures.

Choosing an Aluminum 4x6 pergola means investing in a structure that blends strength, longevity, and low maintenance. From corrosion-resistant alloys to lightweight yet durable frames, aluminum offers a versatile solution for patios, backyards, and terraces. Whether you want a sleek modern look or a practical, long-lasting setup, keenhaipergola.com provides a variety of options to match your outdoor vision, combining quality materials with smart design.